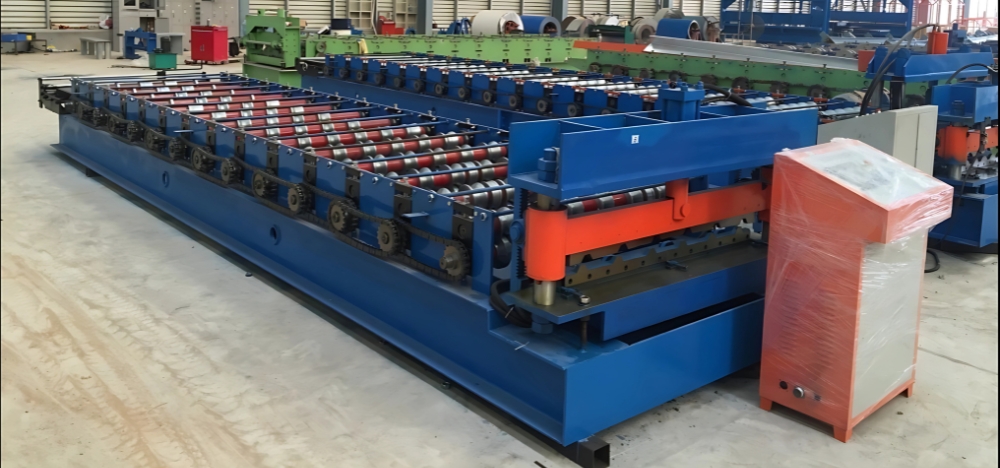

Double Deck Roof Roll Forming Machine

Double Deck Roof Roll Forming Machine

The Double Deck Roof Roll Forming Machine is an advanced, highly versatile piece of machinery designed to produce two types of roof profiles simultaneously, effectively optimizing the production process for roofing panels. This machine is engineered to handle both roofing and wall panels, offering a cost-efficient solution for manufacturers who need to produce various types of metal roofing profiles in high volumes. This machine is particularly beneficial for projects that require different types of panels in the same production line, reducing space, labor, and costs associated with using two separate machines. With its innovative double-deck design, the Double Deck Roof Roll Forming Machine can produce a variety of roofing profiles, such as trapezoidal, corrugated, and tile-like sheets, all while maintaining the highest quality standards.

A Smart Investment for High-Volume Roof Panel Production

The Double Deck Roof Roll Forming Machine is an excellent choice for businesses in the roofing and construction industries that need to produce multiple types of roof and wall panels in large quantities. Its dual-deck design, high-speed production capabilities, and precision forming technology make it a cost-effective, efficient, and flexible solution for manufacturers.

Key Features of the Double Deck Roof Roll Forming Machine

- Dual-Deck Design for Increased Productivity: The defining feature of the Double Deck Roof Roll Forming Machine is its ability to produce two different roof profiles simultaneously. The dual-deck design allows for the creation of both roof and wall panels on a single machine, increasing productivity and saving valuable production space.

- Versatile Profile Options: This machine is capable of producing a wide range of roof profiles, including corrugated, trapezoidal, tile-like, and other customized designs. The ability to switch between profiles without needing to reconfigure the machine ensures flexibility for manufacturers in meeting varying customer requirements.

- Automatic Cutting and Length Adjustments: Equipped with an automatic cutting system, the machine can adjust the cutting length of each panel to meet specific project requirements. The automatic feature ensures precise cuts and reduces manual labor, increasing production speed and accuracy.

- Precision Roll Forming Technology: The machine utilizes advanced roll forming technology to ensure consistent quality and accurate profiles. The rollers are precisely calibrated to form roofing panels with minimal deviation, ensuring that each panel meets the highest quality standards.